ISSUED THE TÜV SE AL OF SAFE T Y

Every pressure cooker lid produced by WMF is tested

under high pressure. The forces involved in the

test are many times stronger than what a lid would

be subjected to during regular use. But only if

the lid functions perfectly under these extreme

conditions is it issued the TÜV seal of safety.

HIGH TECH UNDER HIGH PRESSURE

Every pot is given its shape, a process whereby a

circular blank is deep-drawn under up to 300 tonnes

of pressure. WMF developed Cromargan® especially

for this purpose back in 1927.

mixture of chromium, nickel and stainless steel especially

for this: Cromargan®. It is a rust-proof material with ideal

deformation properties. This means that the pot body can

be

drawn

without damaging the material.

During one of the last steps in the process, the blank is

given another essential quality feature: the TransTherm®

universal base. It’s not just embedded in pressure cookers

but in every WMF pot. An aluminium core is embedded be-

tween the pot body and a magnetic stainless steel circular

blank. The base, which is pressed with a force of up to 1300

tonnes at temperatures of over 500 °C is especially robust

and suitable for all kind of hobs. The way it is designed also

creates the optimum heat distribution inside the pot.

DESIGNED FOR ABSOLUTE PERFECTION

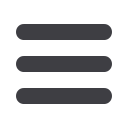

This is the final step in the manufacturing process, but the

pots are far from being ready to hit the shelves. They are then

given the so-called sun-brushed finish in one of the biggest

interlinked robotic grinding machines in cookware production

in the world, which gives the pots their unique elegance.

“There’s no way a machine

could do this job.”

The quality control carefully checks that it has been applied

100 percent. “There’s no way a machine could do this job,”

explains Matthias Moll, process engineer at WMF. Even the

slightest irregularity would cause the pot to be rejected. “Here

at WMF, we’re perhaps a little bit too critical in this respect,”

explains Moll. “The customer wouldn’t even notice such tiny

flaws, but that’s exactly the kind of thing that goes to show

that we strive for absolute perfection.”

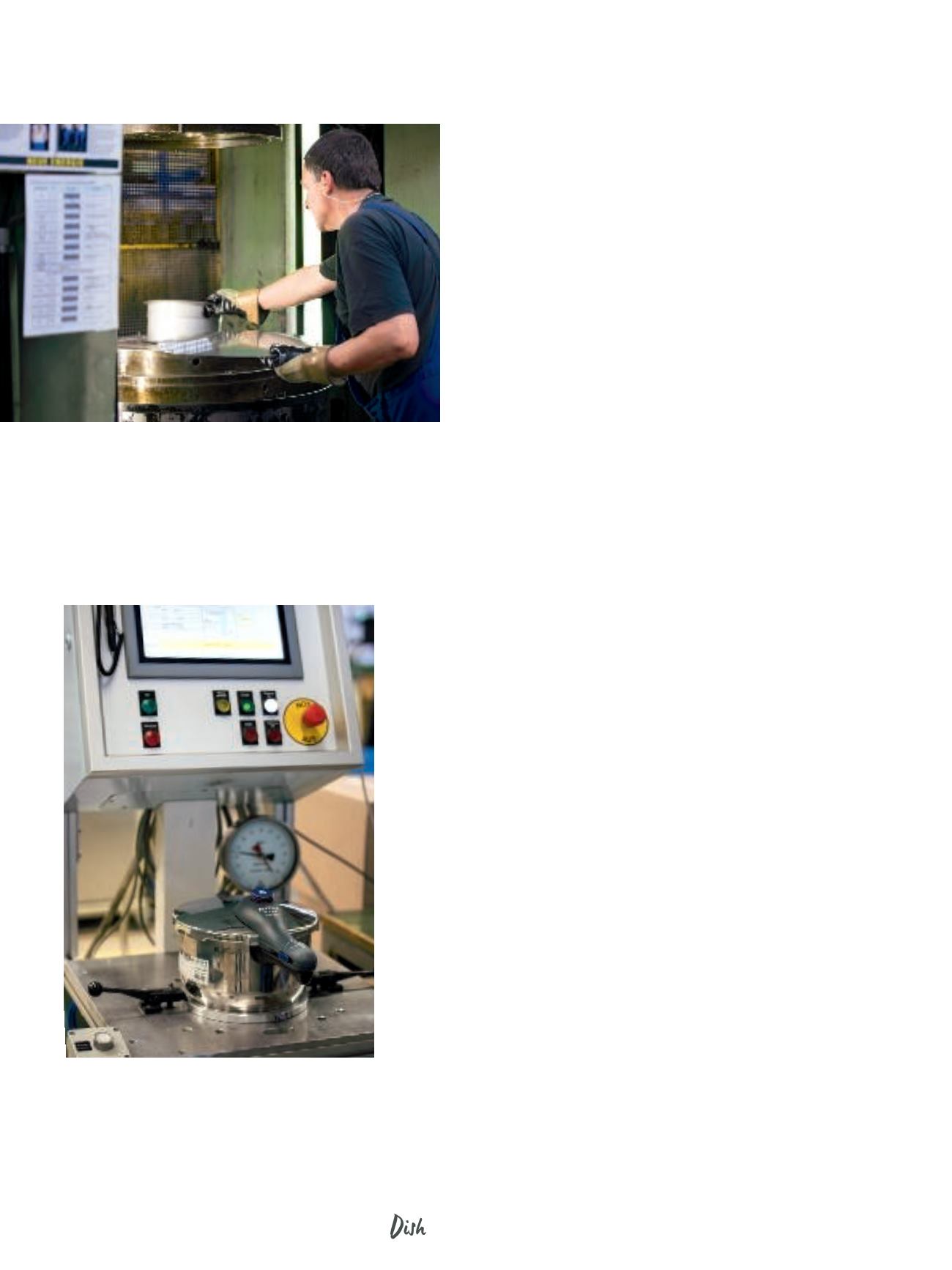

Only now are the grip handles welded on and the base

cambered. The base of the pot is pressed slightly inwards by

a robot using a wooden stamp. If, for example, a pressure

cooker is heated up at a later stage, the cambering offsets

the expansion of the material in the base so that the pot

doesn’t shake. During the final step, an employee then fits

the handles and carries out a final and comprehensive test

of the functions and safety features. This involves putting

the lid on a specially prepared dummy pot and placing it

under high pressure. The forces at work during the test are

several times higher than what the lid would be subjected

to during normal everyday cooking. Only when the lid also

functions perfectly even under these extreme conditions is it

given the TÜV seal of safety. Incidentally, every pot is clearly

marked with a batch number that has been assigned to it.

This way, the entire batch can be recalled in the event of any

quality defects. However, this has never happened even once

in the long and successful history of WMF.

•

K NOW- HOW

by WMF

|

30