860 °C

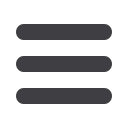

The steel core is made on drawing

presses using the Euler method.

Quality

more

than

ingredients

Step 1

Step 2

Step 4

Step 3

Step 5

The raw materials that are used to

make Silargan® – including feldspar,

quartz and more than 30 other

ingredients – are melted down at

approximately 1300°C.

The pouring rim is

ground and attached

using the plating

procedure.

The basic and surface layers

are applied one after another

and fused into an inseparable

unit at 860°C.

The production process,

one step at a time

Once the handle has been fitted

and a final quality check carried

out, our high-quality Silargan®

products are ready for shipment.

30